Blog

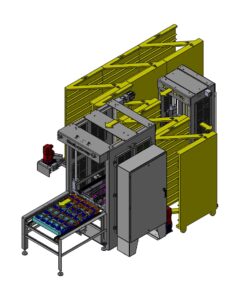

Recently, we’ve installed a Bread Pans UNLOADER in Oregon, a state where we have great friends and customers.

This time we’ll talk about a system for unloading double racks with 3 bread pans per level and a speed of up to 20 per minute.

The system is complemented with an “L” shape Robotrack, a system that allows automating and control of the movement of the racks, providing continuity to the process and thus avoiding stoppages in the exchange of empty racks for full racks. There is always a rack ready to be unloaded, while the elevator unloads the bread pans from the rack shelf. Robotrack is in charge of moving the empty rack forward and putting a full one in its place.

TECHNICAL CHARACTERISTICS:

- • Non-corrosive, stainless steel construction with minimal horizontal surfaces and bakery-proven sanitary design.

- • Compact size, with an approximate area of (5 m2 | 45 sqf)

- • Download speed up to 20 bread pans.

- • Manufacturing time: 6 months

- • Installation time: 3 days

We share the link to a video that we have prepared so you can see how this system works.

Click the link and don’t miss it!!

The engineering and R&D department of Robotray Automation designed a system to move racks without hindering a passage. New RoboSkyTrack is the latest in the movement of racks!!

RoboSkyTrack is an automated overhead system for rack transport via an aerial linear track. A self-powered gantry system allows for a clear passage underneath with seamless integration between 2 RoboTrack lanes. These floor-mounted tracks index racks one-by-one in a first-in first-out sequence. It allows autonomous operation and enhances the overall efficiency of the system, saving additional labor.

We can upgrade to interface directly with rack ovens, opening, and closing doors while removing and pushing in racks.

It is built with materials that withstand down to -40º Celsius, which makes it perfect to integrate into a freezer room.

RoboSkyTrack is characterized by its SECURITY & FLEXIBILITY, as well as…

- Safety sensors at all access points detecting any non-automated motion

- Visual and audible annunciation signals provide system status

- Allows for movement of racks full of product

- Performs lateral movements, inserts, and deposit racks

- Flexible programming, including variable speed

- Stainless steel and anodized aluminum construction are suitable for working down to -40ºCelsius

- Continuous recording of cycle performance with self-diagnostics

- Color HMI Touchscreen, multilingual menus, designed with a simple and easy to use Human-Machine interface

RoboSkyTrack system can be integrated into different configurations, such as entry and exit of proofer and/or freezing rooms. It takes the racks at a designated point and moves them to the different RoboTrack lines. Providing the flexibility to do it in reverse depending on the need of the established process.

We are currently assembling the RoboSkyTrack in our facilities, so we want to share a video of one of the latest tests.

In a few weeks, we will be able to share a video of the installation at its final destination.

Be attentive!

We are pleased to announce the collaboration agreement between BAELTEC Automatisierung and Robotray Automation Systems

- Both companies, with more than two decades of experience in the bakery sector to have decided to open a way of collaboration to expand the services of their customers in Europe.

BAELTEC Automatisierung GmbH was founded by Ingo Muetzel and Markus Weissenberger, they were working 29 years in the baking industry, both can look back to a wide experience as a Senior Service Engineer and Senior Executive in the baking and automation industry, and Robotray Automation, located in Miami with more than 20 years in the sector is specialized in the design and manufacture of automation systems for bakery production processes.

Both companies signed a collaboration agreement at the beginning of last March 2021 to benefit their clients from the combination of their know-how. This union will bring both companies closer to their clients in Europe, offering commercial presence and technical assistance of Robotray in Germany, Switzerland, Austria, Belgium, Netherlands, and Luxembourg. It also allows BAELTEC to improve the offer of automation solutions to its customers, thus completing the catalog.

Both companies intend to improve their offer and services in order to offer the best to their customers.

More offers of solutions and faster and more efficient service. A perfect tandem!

![]()

https://www.linkedin.com/company/baeltec-gmbh/

https://www.linkedin.com/company/robotray/mycompany/

https://www.youtube.com/channel/UCeaMw6P7XI-5A_mX4j3m4Kg?view_as=subscriber

Language: English

Language: English Deutsch

Deutsch Français

Français Español

Español