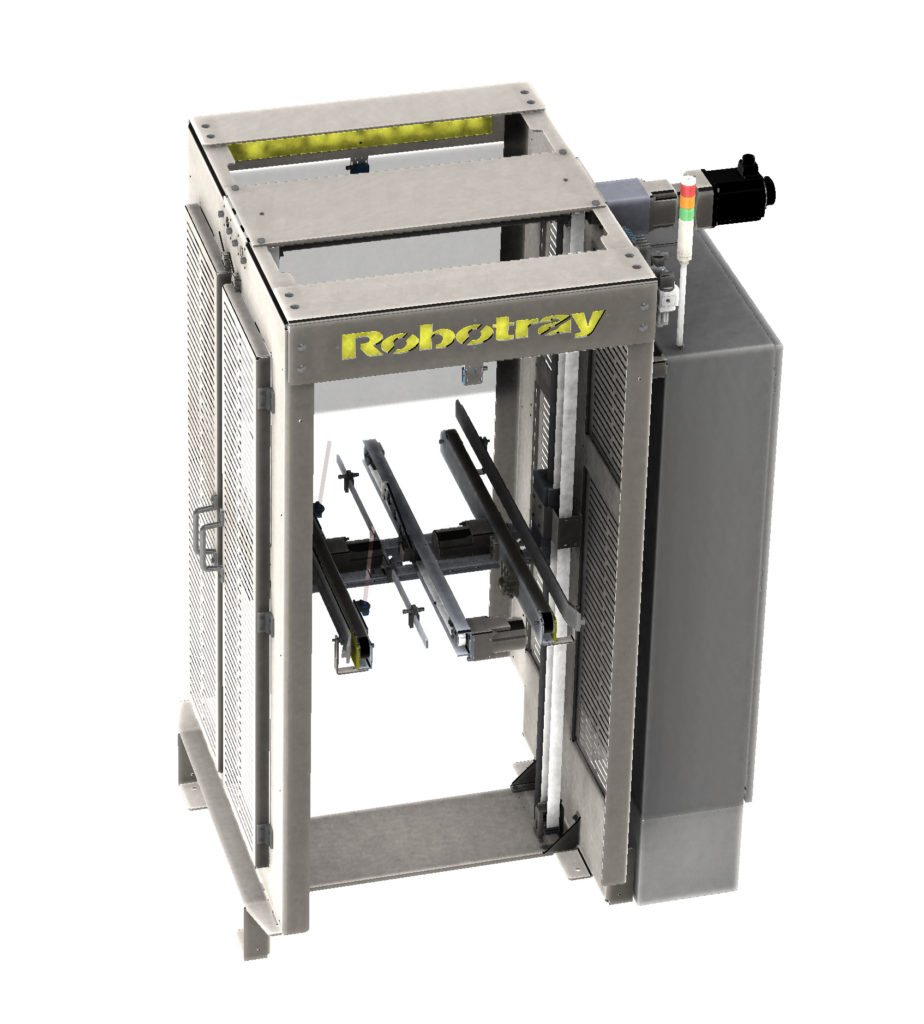

Speeds can be up to 14 trays per minute with a single head unit or up to 28 per minute with the dual head unit, so this is a very fast, efficient and compact system for high throughput industrial requirements. The system is quiet and reliable, open-frame design can be easily cleaned and sanitized, optionally powered-washed to ensure extreme hygiene ad superior food safety. Servomotor elevator system automatically loads trays beginning at the top shelf level. Upon alignment signal and acknowledgment from Robotray, a pusher begins the transfer of trays to each shelf from the Robotray Load conveyor. Robotray then elevates/lower rates to transfer conveyor height. Traveling conveyor then loads next set of trays horizontally. Once again it travels vertically to next unoccupied shelf, delivers trays, and repeats the process until the rack is full. Servomotor controlled motion provides precise positioning and reliable operation, minimizing product disruption.

Servomotor elevator system automatically locates the tray’s position beginning at the top shelf level. Upon alignment signal and acknowledgment from Robotray, a pusher begins the transfer of trays from each rack shelf onto the Robotray conveyor. Robotray then elevates/lowerates to RET Module’s conveyor infeed height. The traveling conveyor then discharges trays horizontally. Once again it travels vertically to RET Module’s conveyor discharge height, retrieves full trays, and loads them back onto the oven rack. It then travels to the next occupied shelf, receives empty trays, and repeats the process until the rack is fully loaded. Servomotor controlled motion provides precise positioning and reliable operation, minimizing product disruption.